Atlas Copco GA75 Air Compressor

The Atlas GA75 air compressor is a highly reliable and efficient equipment used in various industrial applications. Regular maintenance and timely repairs are essential to ensure its long-term performance and avoid unexpected breakdowns. This article provides guidelines for maintaining and repairing the GA75 air compressor and includes key machine parameters.

- Model: GA75

- Compressor Type: Oil-injected rotary screw compressor

- Motor Power: 75 kW (100 HP)

- Air Flow Capacity: 13.3 – 16.8 m³/min (470 – 594 cfm)

- Maximum Pressure: 13 bar (190 psi)

- Cooling Method: Air-cooled

- Voltage: 380V – 415V, 3-phase

- Dimensions (LxWxH): 3200 x 1400 x 1800 mm

- Weight: Approx. 2,100 kg

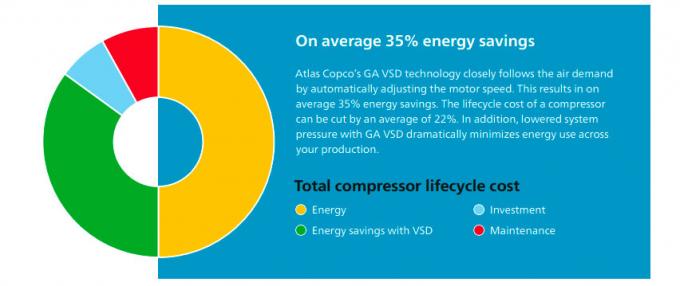

More than 80% of the total lifecycle cost of a compressor is attributed to the energy it uses. Generating compressed air can contribute up to 40% of a facility’s overall electricity expenses. To help reduce these energy costs, Atlas Copco was a pioneer in introducing Variable Speed Drive (VSD) technology to the compressed air industry. The adoption of VSD technology not only results in substantial energy savings but also plays a significant role in safeguarding the environment for future generations. With continuous investments in the development and enhancement of this technology, Atlas Copco now offers the most extensive range of integrated VSD compressors available on the market.

- Achieve up to 35% energy savings during production demand fluctuations, thanks to a wide turndown range.

- The integrated Elektronikon Touch controller manages motor speed and the high-efficiency frequency inverter for optimal performance.

- No energy is wasted through idle times or blow-off losses during standard operation.

- The compressor can start and stop at full system pressure without needing to unload, thanks to the advanced VSD motor.

- Eliminates peak current charges during startup, reducing operational costs.

- Reduces system leakage by maintaining a lower system pressure.

- Fully compliant with EMC (Electromagnetic Compatibility) directives (2004/108/EG).

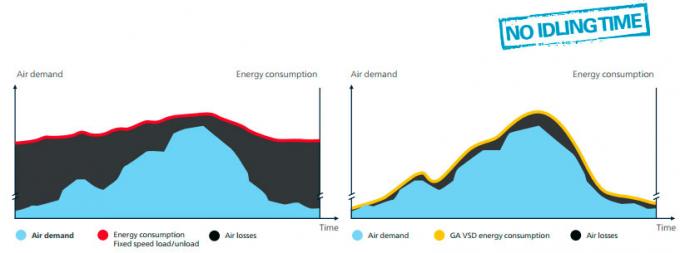

In most production settings, air demand varies due to factors like the time of day, week, or month. Comprehensive measurements and studies of compressed air usage patterns reveal that many compressors experience significant fluctuations in air demand. Only 8% of all installations exhibit a more consistent air demand profile.

1. Regular Oil Changes

The oil in your AtlasGA75compressor plays a crucial role in lubrication and cooling. It’s essential to check the oil level regularly and change the oil according to the manufacturer’s recommendations. Typically, oil changes are required after every 1,000 operating hours, or as per the specific oil used. Be sure to use the recommended oil type to ensure optimal performance.

- Oil Change Interval: 1,000 hours of operation or annually (whichever comes first)

- Oil Type: High-quality synthetic oil recommended by Atlas Copco

2. Air and Oil Filter Maintenance

Filters are vital for ensuring the air compressor operates efficiently by preventing dirt and debris from entering the system. The air and oil filters should be checked and replaced regularly.

- Air Filter Change Interval: Every 2,000 – 4,000 hours of operation

- Oil Filter Change Interval: Every 2,000 hours of operation

Clean filters help prevent unnecessary strain on the compressor and reduce energy consumption. Always use Atlas Copco genuine filters for replacements to maintain compressor efficiency.

3. Inspection of Belts and Pulleys

Check the condition of the belts and pulleys at regular intervals. Worn-out belts can lead to reduced efficiency and cause overheating. It’s important to check for any signs of cracking, fraying, or wear.

- Inspection Interval: Every 500 – 1,000 operating hours

- Replacement Frequency: As needed, depending on wear and tear

4. Monitoring Air End and Motor Conditions

The air end and motor of theGA75compressor are critical components. Ensure they are kept clean, free of debris, and well-lubricated. Overheating or signs of wear may indicate the need for maintenance or replacement.

- Monitoring Interval: Every 500 operating hours or after any major event, such as power surges or unusual sounds

- Signs to Watch For: Unusual noises, overheating, or vibration

5. Draining Condensation

TheGA75 is an oil-injected screw compressor, meaning it generates condensate moisture. To avoid corrosion and ensure smooth operation, it’s important to drain the condensate regularly. This can usually be done through a drainage valve.

- Drainage Frequency: Daily or after each operating cycle

6. Checking for Leaks

Regularly inspect the compressor for any air or oil leaks. Leaks can cause a loss of efficiency and damage the system over time. Tighten any loose bolts, seals, or connections, and replace any worn-out gaskets.

- Leak Inspection Frequency: Monthly or during routine service checks

1. Low Pressure Output

If the air compressor is producing lower pressure than usual, it may be due to an air filter clog, oil contamination, or an issue with the pressure relief valve. Inspect these areas first and clean or replace components as necessary.

2. High Operating Temperature

Overheating can occur if the compressor’s cooling system is not functioning properly. This could be caused by a lack of airflow, dirty filters, or inadequate coolant levels. Ensure the intake and exhaust areas are clean, and replace any faulty cooling components.

3. Motor or Belt Failures

If you hear abnormal sounds or experience vibrations, the motor or belts may be malfunctioning. Check the belts for wear, and if necessary, replace them. For motor issues, contact a professional technician for further diagnostics.

4. Excessive Oil Consumption

Excessive oil consumption can result from leaks or internal system damage. Inspect the compressor for leaks, and replace any damaged seals or gaskets. If the problem persists, consult a technician for a more thorough investigation.

Proper maintenance and timely repairs are crucial to extending the life of your AtlasGA75air compressor. Regular servicing, such as oil changes, filter replacements, and inspection of critical components, will help keep the system running efficiently and prevent major breakdowns.

As aChina Atlas Copco GA75 Parts List Exporter, we provide high-quality replacement parts for theAtlas GA75 air compressorat competitive prices. Our products are sourced directly from trusted manufacturers, ensuring that each part meets the highest standards of performance and durability. We also offer fast shipping to ensure minimal equipment downtime.

Feel free to contact us for more information on parts or to place an order. With our commitment to quality assurance, you can trust us to provide the best service for all your air compressor needs.

| 2205190642 | AFTER COOLER-NO WSD | 2205-1906-42 |

| 2205190648 | AFTER COOLER- NO WSD | 2205-1906-48 |

| 2205190700 | AIR INLET FLEXIBLE | 2205-1907-00 |

| 2205190720 | CORE SUPPORT TRANSITION | 2205-1907-20 |

| 2205190772 | BACKCOOLER CORE ASS. | 2205-1907-72 |

| 2205190781 | FRAME ASSEMBLY | 2205-1907-81 |

| 2205190800 | OIL COOLER | 2205-1908-00 |

| 2205190803 | OIL COOLER | 2205-1908-03 |

| 2205190806 | COOLER-FILME COMPRESSOR | 2205-1908-06 |

| 2205190809 | OIL COOLER YLR47.5 | 2205-1908-09 |

| 2205190810 | OIL COOLER YLR64.7 | 2205-1908-10 |

| 2205190812 | OIL COOLER | 2205-1908-12 |

| 2205190814 | OIL COOLER | 2205-1908-14 |

| 2205190816 | OIL COOLER | 2205-1908-16 |

| 2205190817 | OIL COOLER | 2205-1908-17 |

| 2205190829 | GEAR PINION | 2205-1908-29 |

| 2205190830 | GEAR DRIVE | 2205-1908-30 |

| 2205190831 | GEAR PINION | 2205-1908-31 |

| 2205190832 | GEAR DRIVE | 2205-1908-32 |

| 2205190833 | GEAR PINION | 2205-1908-33 |

| 2205190834 | GEAR DRIVE | 2205-1908-34 |

| 2205190835 | GEAR PINION | 2205-1908-35 |

| 2205190836 | GEAR DRIVE | 2205-1908-36 |

| 2205190837 | GEAR PINION | 2205-1908-37 |

| 2205190838 | GEAR DRIVE | 2205-1908-38 |

| 2205190839 | GEAR PINION | 2205-1908-39 |

| 2205190840 | GEAR DRIVE | 2205-1908-40 |

| 2205190841 | GEAR PINION | 2205-1908-41 |

| 2205190842 | GEAR DRIVE | 2205-1908-42 |

| 2205190843 | GEAR PINION | 2205-1908-43 |

| 2205190844 | GEAR DRIVE | 2205-1908-44 |

| 2205190845 | GEAR PINION | 2205-1908-45 |

| 2205190846 | GEAR DRIVE | 2205-1908-46 |

| 2205190847 | GEAR PINION | 2205-1908-47 |

| 2205190848 | GEAR DRIVE | 2205-1908-48 |

| 2205190849 | GEAR PINION | 2205-1908-49 |

| 2205190850 | GEAR DRIVE | 2205-1908-50 |

| 2205190851 | GEAR PINION | 2205-1908-51 |

| 2205190852 | GEAR DRIVE | 2205-1908-52 |

| 2205190864 | GEAR DRIVE | 2205-1908-64 |

| 2205190865 | GEAR PINION | 2205-1908-65 |

| 2205190866 | GEAR DRIVE | 2205-1908-66 |

| 2205190867 | GEAR PINION | 2205-1908-67 |

| 2205190868 | GEAR DRIVE | 2205-1908-68 |

| 2205190869 | GEAR PINION | 2205-1908-69 |

| 2205190870 | GEAR DRIVE | 2205-1908-70 |

| 2205190871 | GEAR PINION | 2205-1908-71 |

| 2205190872 | GEAR DRIVE | 2205-1908-72 |

| 2205190873 | GEAR PINION | 2205-1908-73 |

| 2205190874 | GEAR DRIVE | 2205-1908-74 |

Post time: Jan-04-2025